Restore Flange Integrity

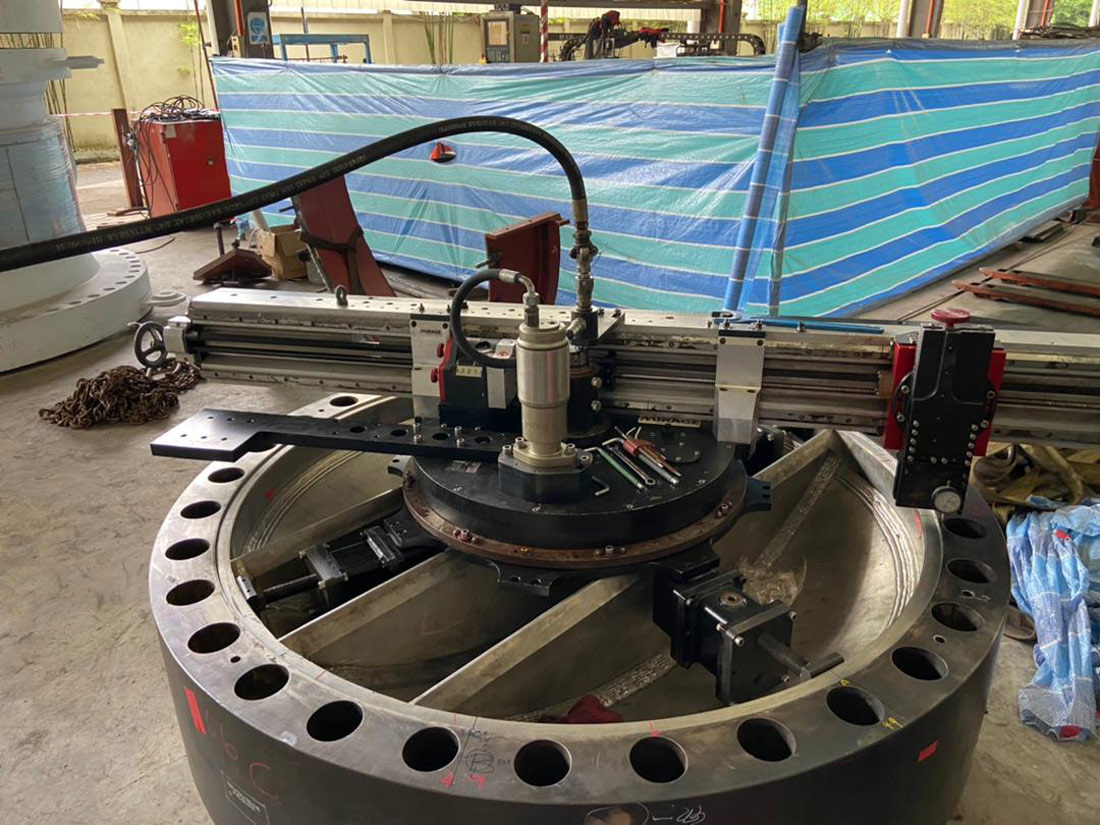

Damaged flange faces can lead to leaks and costly unplanned shutdowns. Velcorix provides specialist on-site flange machining services to re-face and restore sealing surfaces without the need to cut and remove the pipe.

Our portable machines can be mounted internally or externally, capable of machining a wide range of diameters from 2 inches up to 120 inches.