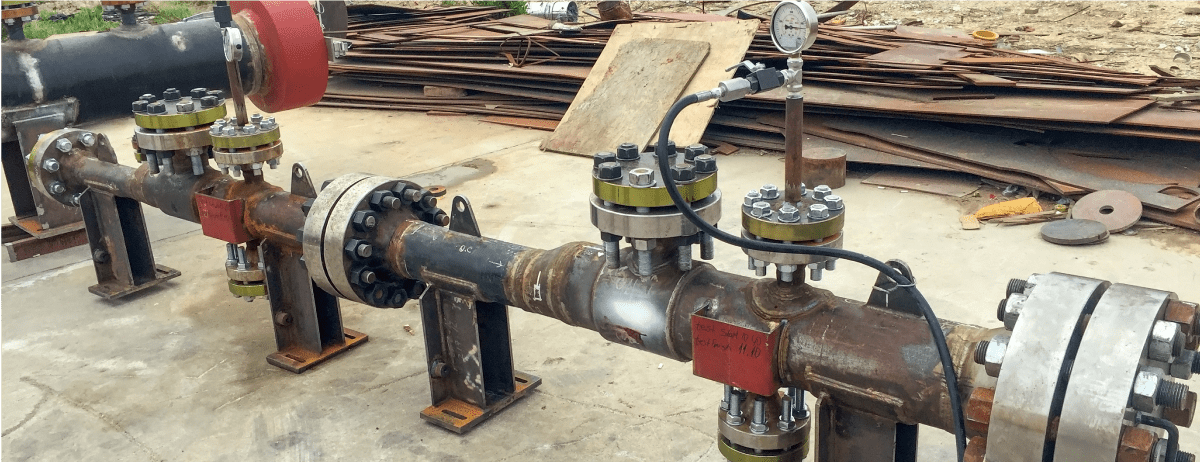

Precision Pressure Verification

Pneumatic testing uses air or inert gas such as nitrogen to verify the integrity and leak-tightness of pipelines and pressure vessels. Unlike hydrostatic testing, it is suitable for systems where water contact is prohibitive or for detecting very small leaks.

Velcorix conducts these high-risk tests with meticulous planning, exclusion zones, and remote monitoring to ensure absolute safety and compliance with ASME/API standards.